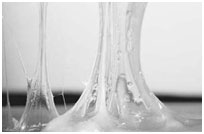

Thickeners are used to hold the printing paste in the screen and control the amount of paste that is transferred to the fabric. They allow the paste to level in blotch printing and prevent flushing or bleeding and let the paste penetrate to the required extent. We provides both synthetic and natural thickeners.

Binders

Binders are used in pigment printing to crosslink and bind pigment particles to the fiber and improve fastness properties

Formulated using high-grade ingredients, these chemicals are in compliance with the set industry standards and norms. Owing to their features like stability and high solubility, these chemicals are widely demanded by the clients. Moreover, the offered chemicals are tested on various parameters so as to ensure their accurate composition and effectiveness.

For the textile screen printing industry, We offers Table Gum. The product offers very good adhesion properties, excellent tack and just the right viscosity for applying onto the table for sticking the garment pieces on the table for printing process. The product doesn’t get transferred onto the garment and that’s the best part about the product.

Textile SoftnerSoftner (Q) is an excellent product for cotton and polyester blended fabric. This is a pseudo cationic softner 100%. It does not give bad smell of tallow (which other softner give). It is non yellowing while ironing on white fabrics. No acetic acid is required for cationisation (which other softner required), that means there is no need for acetic acid to add in it.

Regular Fixer/Additives

We have wide range of Nylon Fixer, Flock Fixer, Silicon Fixer,Oxal. Eco-friendly Adding 3~5% can increase washing fastness for elastic fabrics.

Discharge AgentsDischarge agents are reducing agents that discharge reactive dyed grounds in pigment printing. We have No smelling Discharge Agents.