|

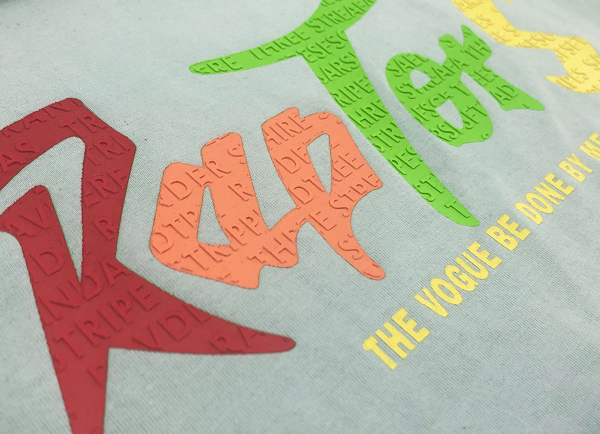

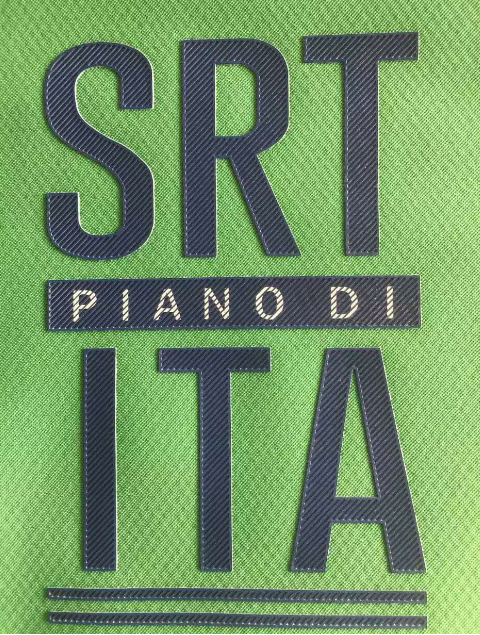

RT056 HD Paste

(Machine) |

RT058 HD Paste

(Table) |

RT051 Lightweight HD

Paste |

| RT064W PU HD Paste | RT064C PU HD Paste |

R&T guarantees the products qualities. However all the recommendations are done without any responsibility because R&T cannot control the conditions of the applications.